Special tools have a special place in our hearts. Of course, you can sometimes improvise with another tool and do the job just fine, albeit taking longer and working harder than needed. But other times, you can mess up big time and do more harm than good. With some jobs, “just good enough” is simply not enough. And, in those cases, cheaping out can cost you a lot more in the end.

For example, a simple job like changing a flat tire could be very unpleasant or even dangerous if done incorrectly. In the best-case scenario, you’ll just end up losing a bolt or even snapping it, but you can also end up looking at your wheel going straight while you enter the next corner!

Other times, using the proper tool for a job can also save you a lot of time and money. Just imagine taking off an oil filter on a ’99 Lexus RX300 without the proper tools or really really tiny hands? Yeah, sure, you can improvise and still use 3 different tools, take up twice the same time and potentially end up damaging other components by not correctly tightening the oil filter.

This is why it’s always wise to invest in special tools that are designed for a specific purpose. Not only will it save you time and money, but it will also make your life a lot easier.

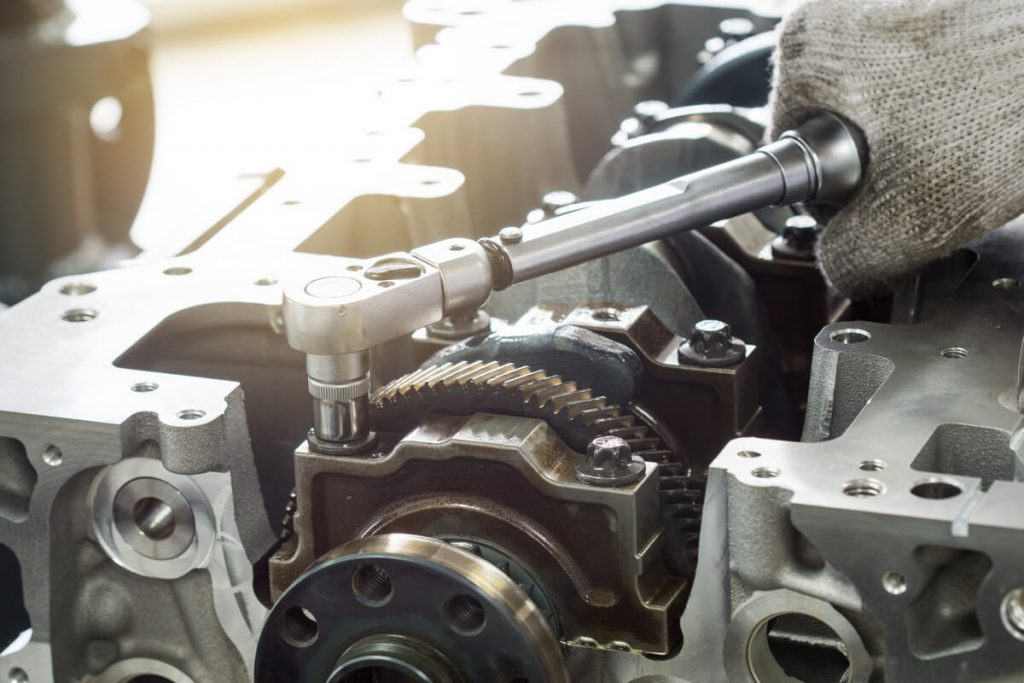

A torque wrench is exactly that. Yes, you can do without 98% of the time. But when you come across bolts that need to be tightened to a specific torque, (the most well-known being head bolts), just eyeballing it is never a good idea. If you know your way around cars and do more than just regular maintenance, there’s no way around it; you’ll need a torque wrench.

To help you find the right torque wrench for you (since it’s not that easy at all given the plethora of types and sizes available), we’ve created this piece explaining what a torque wrench is, what it does, and the different types currently on the market. Once you know a little more about this essential special tool, you’ll better understand why you absolutely need to add one (and maybe two) in your tool chest.

What is a Torque Wrench, and What is It Used for?

A torque wrench is basically a ratchet that enables you to control the specific amount of rotational force applied to any screw, bolt, or nut. A torque wrench keeps you from overdoing it, tightening the bolt too much, which could cause it to or damage the screw thread, or the other extreme, where you don’t apply enough force. Of course, no need to mention that a bolt that isn’t torqued hard enough would risk loosening and could eventually drop to the floor.

Torque wrenches come in various dimensions and types as they are used for almost endless applications. For example, you should use a torque wrench for tightening your car’s wheel bolts (although you might be better with a torque stick to tighten lug nuts), all those suspension nuts and bolts, anything related to internal engine components, or while working on your brakes, and so on.

As regular ratchets, torque wrenches use sockets of various dimensions and are divided according to drive type:

- 1/2-inch drive

- 3/8-inch drive

- 1/4-inch drive

Which one you’ll want will depend on what you intend to use it on. 1/2″ drive torque wrenches will usually be reserved for lug nuts, suspension, and steering components as well as head bolts. On the other hand, 3/8″ drive models are suitable for pretty much everything else smaller than that. Lastly, 1/4″ torque wrenches would probably be intended to be used on smaller electronics and such, but to be honest, aren’t really useful in automotive applications.

Of course, bigger torque wrenches have a higher torque range than smaller ones, so that will also play in the decision. Even if you wanted to use your 3/8″ wrench to tighten your new head bolts set or lug nuts, it’s very unlikely that it would go that high and you would have to put way too much effort into it for nothing. Never forget to always use the right tool for the job!

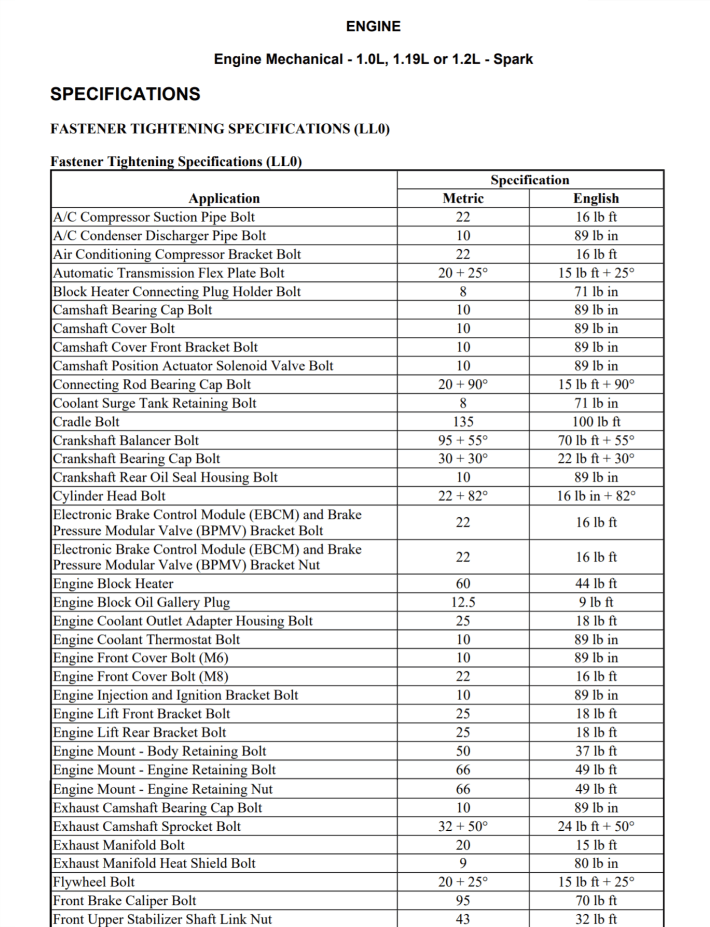

It’s also important to mention that, knowing how to properly use a torque wrench is not all. You also have to know what is the required torque for that specific bolt. Luckily, for some bolts, there are some general rules. For instance, when it comes to lug nuts, 90 lb-ft is usually enough for cars and 110lb-ft is usually enough for trucks.

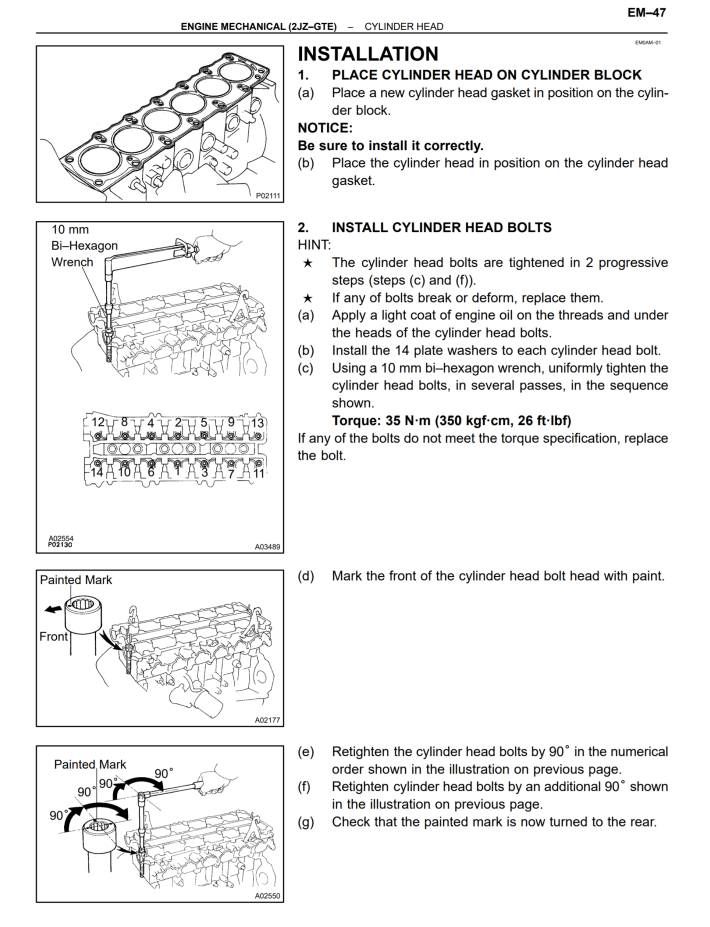

But for head bolts for instance, not only will you need to know the specific torque, but they sometimes have to be torqued according to a specific sequence. If the sequence is not respected, you risk the gasket not sitting evenly, which could cause significant problems in the very short run.

To find out almost any bolt’s torque specification, you’ll need to get your hands on your car’s repair manual. Luckily, you can easily find OEM repair manuals in pdf format online and they are quite inexpensive—a lot cheaper than blowing an engine due to an improper tightening sequence.

When it comes to torqued bolts, never improvise!

Types of Torque Wrench

Click-Type Torque Wrench

Click-type torque wrenches, by far the most common type in the automotive industry, are simple to use as it has an engraved scale used to set the required amount of torque on the handle and makes a click sound when reached. The adjustment itself is pretty straightforward.

First, unlock the lock knob (often by either twisting the bottom or turning the little button). After that, set the required torque by twisting the handle and lock it back.

For example, the right amount of torque required to properly tighten lug nuts on a car is around 90-100 lb-ft. Set the handle to that value, lock it and you are ready to go. Tighten the lug nuts by hand or using a ratchet. Then, take out the torque wrench and torque the nuts. Once the specified value is reached, you’ll hear a loud click that you might also feel in the handle.

That’s it. Simple as that!

Beam-Type Torque Wrench

Beam-type torque wrenches are made of two bars. One bar has a chart on which you have a scale, again in imperial and metric values, and a handle with which you tighten the bolts. As you tighten the bolt, you’ll see the needle move, indicating the amount of torque applied.

It’s important to mention that the bar with the needle is designed to flex under force which makes it pretty fragile, and it needs to be handled properly to show the correct value. Beam-type torque wrenches are just as accurate as any other but require a lot more care, which may explain why they are not that used anymore.

Split Beam-Type Torque Wrench

Split beam torque wrenches are very precise and the design makes them pretty robust. They are also very similar to click-type ones. Simply flip the lock lever open, rotate the knob to the desired value, and lock the lever back. When the specified value is reached, you’ll hear a click, created by one of the beams inside the torque wrench being released by the trigger, stopping the wrench from applying more force than the desired torque setting.

What makes split beam torque wrenches special is that they often have a flex head, making them easier to fit in tight space, necessitating weird angles, where other wrenches can’t reach.

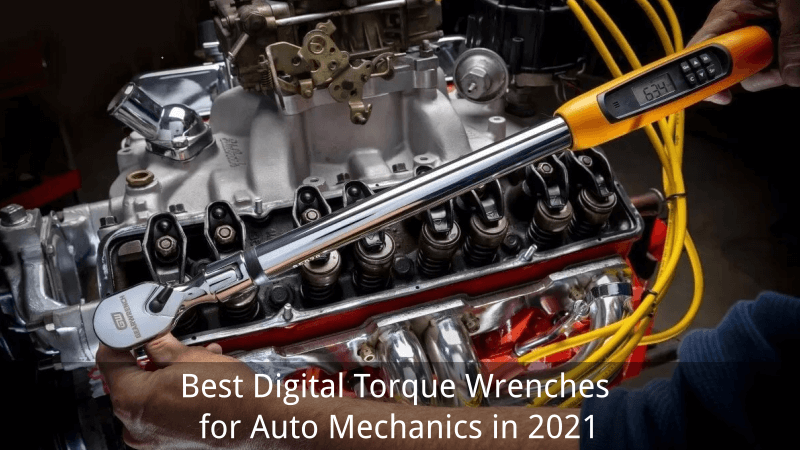

Digital-Type Torque Wrench

With a Digital torque wrench, you can just dial in the desired amount of torque on the digital display and start tightening bolts. Depending on the model, some torque wrenches will click, sound a beep or even flash some LEDs once the required torque is reached.

Digital torque wrenches are quickly increasing in popularity due to the much more user-friendly process. Moreover, depending on the manufacturer, you can sometimes store your most frequently used torque values and use them at will. This feature comes in especially handy if you work in a dealer and frequently work on the same cars or on an assembly line, repeating the same tasks over and over. Digital models are simply far easier to use than any other model out there.

On the other hand, the digital display makes them more fragile, they require batteries and often cost a lot more than mechanical models.

Slip-Type Torque Wrench

Slip torque wrenches are also very similar to click-type models. They have a lock at the bottom of the handle that needs to be unlocked to adjust the required value. The main difference is in the wrench’s construction and the way it limits the applied torque.

Instead of clicking when reaching the set value, the ratchet mechanism will “slip”, almost like if it was skipping teeth. The innovative mechanism makes it virtually impossible to overtorque a bolt.

For having tried a couple of models before, they work superbly well. However, I’m not sure why, they are definitively not that common in the automotive industry.

Torque Stick

Torque Sticks are for those who work fast and don’t have much time to fiddle with adjusting torque values. Indeed, torque sticks are basically impact wrench extensions, each calibrated to a specific value. Just pick the right stick and that’s it. Once the set torque is reached, the stick will “twist”, preventing any more torque to be applied.

However, torque sticks are far from being gentle and thus, are only really suitable to torque lug nuts. Never, never use a torque stick for anything smaller or requiring a precise torque sequence, such as cylinder head bolts. Never.

Torque sticks are only meant to speed up the process of tightening wheels when working in a shop and removing 8-10 wheelsets a day. If you only work on your own car, you’re better off saving that money and spending it on a conventional, and much more versatile torque wrench.

Read more: Best Torque Sticks to Properly Tighten Lug Nuts

Last Words

As much as every other amateur mechanic would like to tell you that special tools are for dummies and that you can basically cheat the system by using whatever works and save money at the same time, it’s totally the opposite.

When it comes to applying a specific torque to a bolt, torque wrenches are essential. Ask any serious mechanic. If he tells you otherwise, well he’s not a serious mechanic and you should probably find another. Special tools like torque wrenches are designed to make your life easier. They will not only save you from damaging car parts that you are working on but also from the consequences of those damages. And we’re not talking just about financial losses here.

We are talking about safety, as parts like suspension, brakes, and wheels are not something to be messed around with carelessly. Choose wisely your preferred type and don’t cheap out. Quality torque wrenches are usually very robust and durable and should last you a long time.

And once again, “always use the right tool for the right job!”—you’ll thank me later!

![Best Tire Changers for Amateurs and Professionals [2022 Review]](https://garagespot.com/wp-content/uploads/2022/01/Best-tire-changer-e1652905942544-compress-211x150.jpg)